Site assessment

Review facility size, insulation, airflow pathways and cold spots to guide equipment sizing.

Heat treatment eliminates insects across life stages through protein denaturation, loss of enzyme activity, and desiccation without chemical residues.

Modular wheel-mounted heaters with thermostat control help achieve stable heat throw and uniform treatment coverage.

Concept

A heat-based pest control method that eliminates insects using controlled temperature and time supporting cleaner operations and safer environments.

Heat treatment causes insect mortality through denaturation of proteins, loss of enzyme activity, and desiccation.

We focus on protecting your environment and health by providing an environmentally friendly fumigation solution.

Services

From equipment supply to site deployment planning built for repeatability and operational comfort.

Review facility size, insulation, airflow pathways and cold spots to guide equipment sizing.

Modular equipment with practical setup approach for warehouses and industrial environments.

Support for achieving target temperature distribution and holding time for effective treatment.

Basic checklists + repeatable workflow to assist your operational teams.

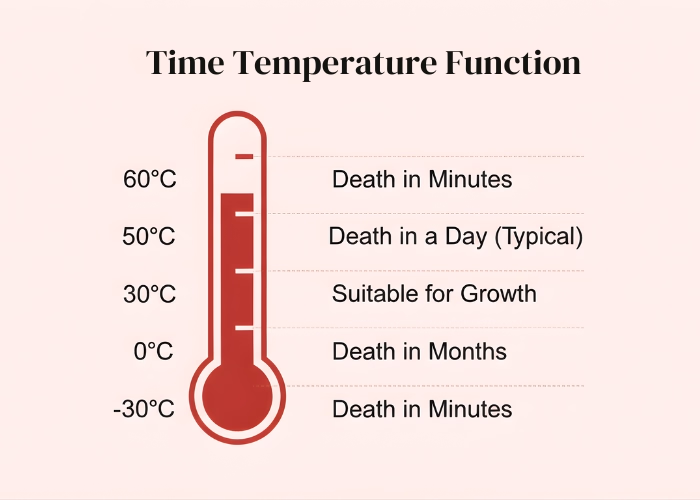

Time–Temperature Function

Reliable results require both reaching target temperature and maintaining it long enough for full kill.

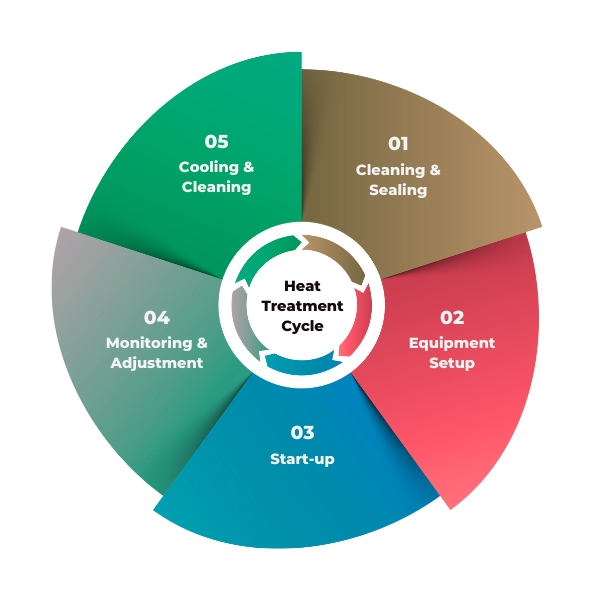

Workflow

A structured workflow ensures consistent temperature distribution, prevents stratification, and supports repeatability.

Clean the area thoroughly. Focus on pest hiding and egg-laying spots and limit air leaks.

Deploy hot air blowers, power distribution and recirculation fans to avoid cold spots.

Bring the facility to target temperature and stabilise airflow distribution.

Maintain 50–60°C for 24–48 hours. Adjust airflow/ducting to prevent stratification.

Controlled cool-down and post-treatment cleaning before returning the space to service.

Applications

Suitable for sectors where clean pest control is preferred.

Food processing, farming, mills, and bakeries.

Pet food and animal feed industries.

Residential, dormitories, and institutions.

Hotels, motels, and youth hostels.

Trains, airplanes, and vehicles.

Tobacco, textiles, and retail stores.

About

iEngineering delivers practical, high-quality solutions across industrial hardware, energy systems and specialised machinery. Our heat-treatment Green Fumigation solution supports clean pest control for food and industrial environments backed by engineering capability and reliable deployment support.

At iEngineering Australia, our mission is to enhance efficiency, ensure quality control, and deliver customer satisfaction through innovative engineering solutions. We are committed to global standards and sustainable solutions that create long-term value for our clients and communities.

To be a trusted engineering partner across Australia, Fiji, India and the Pacific—delivering intelligent, resilient and low-carbon infrastructure for utilities, industry and the built environment.

We operate with integrity, safety and accountability. Our team focuses on practical innovation, clear communication and long-term partnerships so that every project delivers real operational and commercial benefits.

Our Journey

Founded in 2013, iEngineering Australia delivers a comprehensive range of high-quality electrical and energy hardware solutions tailored for Australian and Pacific conditions. From design and engineering to manufacturing, testing, and commissioning support, we ensure every product whether switchboards, transformers, oil filtration machines, solar systems, Green Fumigation Machine and EV chargers is safe, reliable, and built to last.

Where We Operate

iEngineering Australia operates across Australia, Fiji, and India, delivering reliable technology and asset management solutions to organisations of all sizes from local enterprises to large multinational companies.

Phone: +61 (02) 8318 1490

Email: enquiries@iengaust.com.au

Warawara Cct, Quakers Hill NSW 2763, Australia

View mapPhone: +91 9168627258

Email: shila@iengaust.com.au

Navale IT Zone, Office No. 501, 5th Floor, A-Wing, Near Navale Bridge, Mumbai-Bangalore Highway, Narhe, Pune – 411041.

View mapPhone: +679 9488589

Email: enquiries@iengaust.com.au

Suva, Fiji.

View mapFAQ

Quick answers for operations, safety, and planning.

Share facility size, layout, and target pests we’ll recommend the right setup approach.